Pre-Insertion Resistor & Zero Missing Phenomenon

|

| Inside of PIR |

Large generation of reactive power occurs in HVAC due to the capacitance of the long transmission lines and cables.

To compensate the

reactive power, shunt reactors are typically installed. Due to their inductive characteristics,

these can raise other technical challenges within the system.

The current in the inductor should maintain its continuity and when it is connected at a voltage

zero, the current will have a DC component with an amplitude equal to the amplitude of the AC component.

The duration of the DC component depends on the resistance of system components e.g. resistance of shunt reactor winding,

external grid, export cable and transformers.

If the inductor is

connected at a peak voltage, no DC component will be present because the

current will be zero at that moment.

The capacitive current

of the cable and transmission line are leads system voltage by 90 degrees, and inductive current of the shunt reactor lags by 90 degrees.

If energized at voltage

zero, both the inductive and capacitive currents are in phase opposition to

each other and tend to cancel out. This leaves a DC current in the incoming

breaker, with no zero crossing for a period of time.

During this period it

is not feasible to re-open the circuit breaker (e.g. if a fault in the cable

exists) because the circuit breaker should find the current zero for an arc

interruption. This can take a long time (sometimes seconds) to attain. Hence,

it is called zero missing phenomenon (ZMP).

There are different

mitigation methods addressed in the article for ZMP and the application of any particular the method depends on the system conditions like operating voltage, cable length

and location of the system.

Fig. 1 shows the

current for the cable or (transmission line) and shunt reactor in phase opposition. These two currents

cancel each other out, leaving the DC component.

The magnitude of the DC

component depends on the amount of compensation, where lower shunt compensation

results in a lower DC component. The ZMP can theoretically be avoided by limiting

the compensation to less than 50%.

However, this may

increase transient overvoltage, and cause the need for a larger STATCOM / SVC

for meeting grid code reactive capability requirements.

EFFECT OF SYSTEM PARAMETERS ON ZERO MISS DURATION:

The duration of ZMP

depends on various parameters of the system. It is important to determine the

maximum zero miss duration (ZMD) before implementing any mitigation methods.

A. Switching angle

The maximum ZMD is

observed when the circuit breaker is switched at voltage zero (simultaneous or

single pole). There is no ZMD observed for the circuit breaker when switched at

voltage peak (single pole).

B. Grid short circuit strength

The damping of the DC

component of the shunt reactor current during energization, and during faults, depends

upon positive and zero sequence impedance of the grid.

The resistance for

maximum fault level is less as compared to the minimum fault level, which therefore

leads to slower damping of the DC component

C. Degree of compensation

The maximum ZMD is at

100% compensation when the capacitive and inductive currents completely cancel

each other out and only the DC component remains.

Above 100% compensation, the inductive current is greater than capacitive current, and hence, only some AC

component remains, resulting in a reduction of the ZMD. There is no ZMD below 50%

compensation provided the shunt reactor has a minimum resistance to damp out

the DC component.

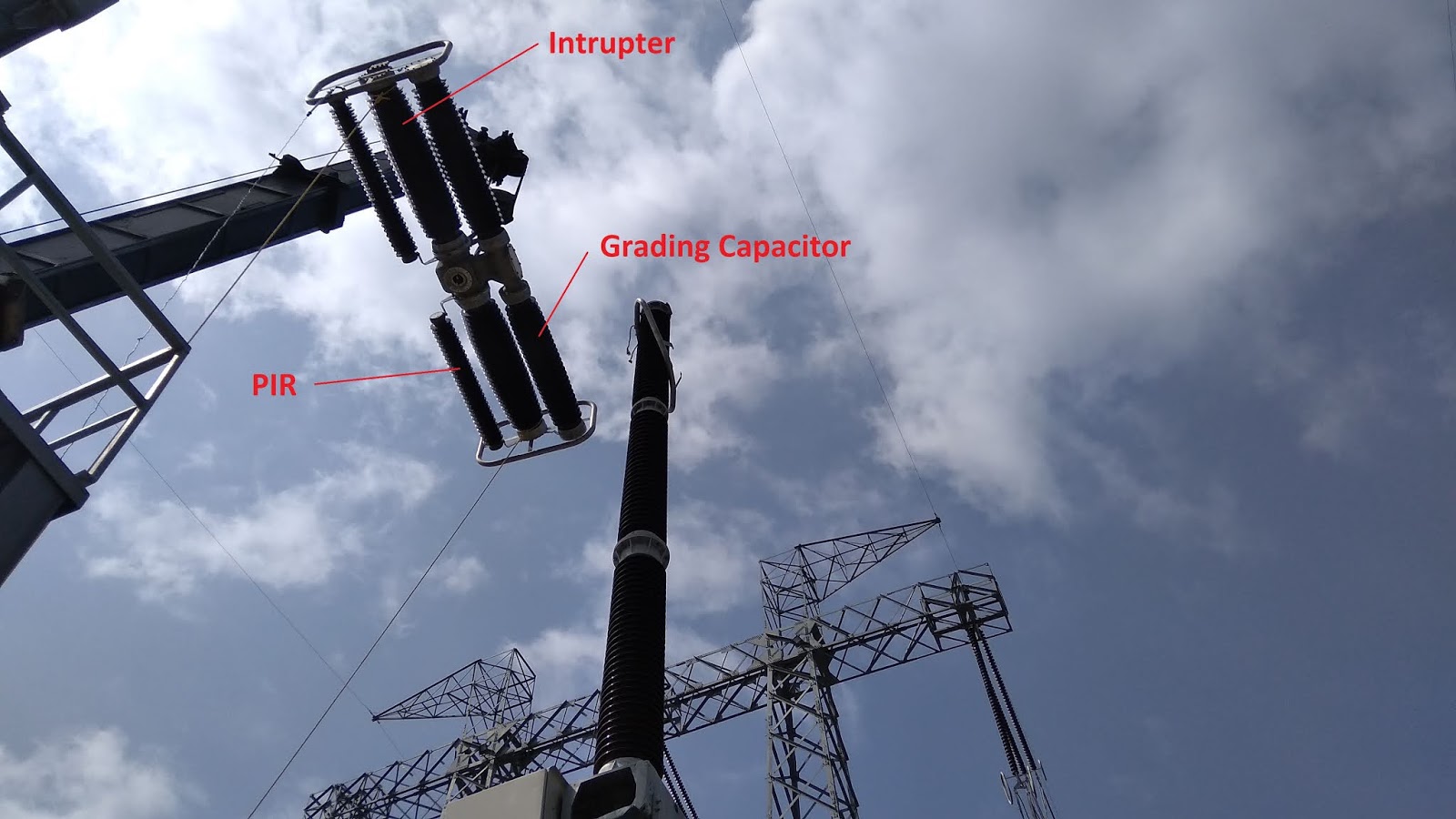

PRE-INSERTION RESISTOR:

Circuit breakers with

pre-insertion resistors (PIR) are often installed to damp out the transients

during energization. There are basically two different PIR configurations:

parallel and series PIR.

In parallel PIR configuration (Fig. 3a), the resistor

switch is in series with the resistor bank, and both are in parallel with the

circuit breaker interrupter, where the interrupter operation follows the PIR

switch operation.

In a series PIR configuration (fig. 3b), the resistor switch

is in series with the circuit breaker interrupter but in parallel with the

resistor bank.

The different characteristic quantities of a circuit breaker with closing

resistors as shown in Fig. 4

The closing time

interval is defined as time between energizing the closing circuit, the

circuit-breaker being in the open position, and the instant when the contacts

touch in all poles.

The make time

interval is the time between energizing the closing circuit, the

circuit-breaker being in the open position, and the instant when the current

begins to flow in the first pole.

Pre-arcing time

interval is the time between the initiation of current flow in the first pole

during a closing operation, and the instant when the contacts touch in all

poles for three-phase conditions, and the instant when the contacts touch in

the arcing pole for single-phase conditions.

For a parallel PIR,

PIT is defined as the interval of time during a closing operation in any one

pole between the instant of contact touch of resistor switch, and the instant

of contact touch in the main breaking unit of that pole.

For circuit breakers having

series connected PIR, the PIT is defined as the interval of time between the

instant of the last contact touch in any closing resistor element, and the

instant of the last contact touch in any main breaking unit.

From the above

definition, the PIT for both the configurations are different for different phases.

The PIT mentioned in this paper is the time for which the resistor in each pole

is in circuit before the contact touching of the main breaking unit of that

pole.

The standard also

specifies typical manufacturing tolerances for resistors to be considered. If a

manufacturer has been selected, they should state the value of these

tolerances.

In addition, they should state the range of PIR insertion times which

they can achieve (including time tolerances), as these are typically realized

mechanically, and therefore depend on the physical design and ambient

conditions.

Comments

Post a Comment